GENMBR ® Membrane Bioreactor ModulesGENMBR®️ Innovative Membrane Bioreactor (MBR) Modules

What is GENMBR ®?

GENMBR ®, a membrane bioreactor module, has been developed for the biological treatment and recovery of domestic and industrial wastewater.

In conventional activated sludge systems, which is the biological treatment process of wastewater, the water we treat is separated from the sludge with the final sedimentation tank. In MBR systems, GENMBR ® modules, which are a physical barrier, provide separation of treated water. Thus, the sludge concentration and sludge age in the aeration tank are high. Besides that the operational problems in the settling tank are eliminated. In addition, the required aeration tank volume is lower.

Scope of Application

GENMBR ® provides is high quality effluent water. Also provides many benefits to our customers in domestic or industrial wastewater recovery. In industrial factories that pay a certain fee for water, we recover wastewater and reuse it in production processes.

You can make a difference for your facility by reaching ZLD (Zero Liquid Discharge), ZDHC (Zero Discharge Hazardous Chemicals), and Inditex standards, especially for the textile industry, with the recycling projects we have designed. In addition, as a result of the TÜBİTAK audit, which is the most up-to-date development regarding wastewater recovery in the textile sector, you can obtain significant tax deductions.

Wastewater recovery plants with our membranes, meet their own depreciation in a short time. In this way, you can turn your wastewater into a source of income. You can also add prestige to your company with innovative solutions for integrated wastewater management.

GENMBR ® modules are modular systems suitable for capacity increase and development of conventional activated sludge systems. We produce special solutions for your needs. We are restructuring your facility by increasing the capacity of the GENMBR ® systems, which are operated with high sludge age, with our treatment plant capacity increase and various sizes of module options.

You can contact us for detailed information about our application areas.

Advantages of the GENMBR ® System

- As we operate with high sludge age, the treatment efficiency is higher. We obtain higher quality product water than conventional activated sludge systems.

- The ability to work at high MLSS concentrations enables high capacity purification in a low volume aeration tank.

- We do not use a settling tank, which covers a large area.

- We ensure the protection of natural resources through the recovery of wastewater.

- The amount of sludge to be removed from the system is lower than the conventional system. It reduces the capacities of sludge processes.

- In addition, since the mud is stabilized in the membrane pool, it eliminates the odor problem. It also reduces the polymer dosage required for stabilization.

Advantages of GENMBR ® Modules

- Efficient use of space with high packaging rate,

- Mechanical design suitable for backwashing,

- High aeration efficiency with 3-point air scouring,

- PVDF membrane with high chemical resistance,

- Minimum energy requirement with low pressure,

- High purification efficiency with 40 nm pore diameter,

- 5 times stronger membranes with PET backing layer.

You can find detailed information about GENMBR® advantages here.

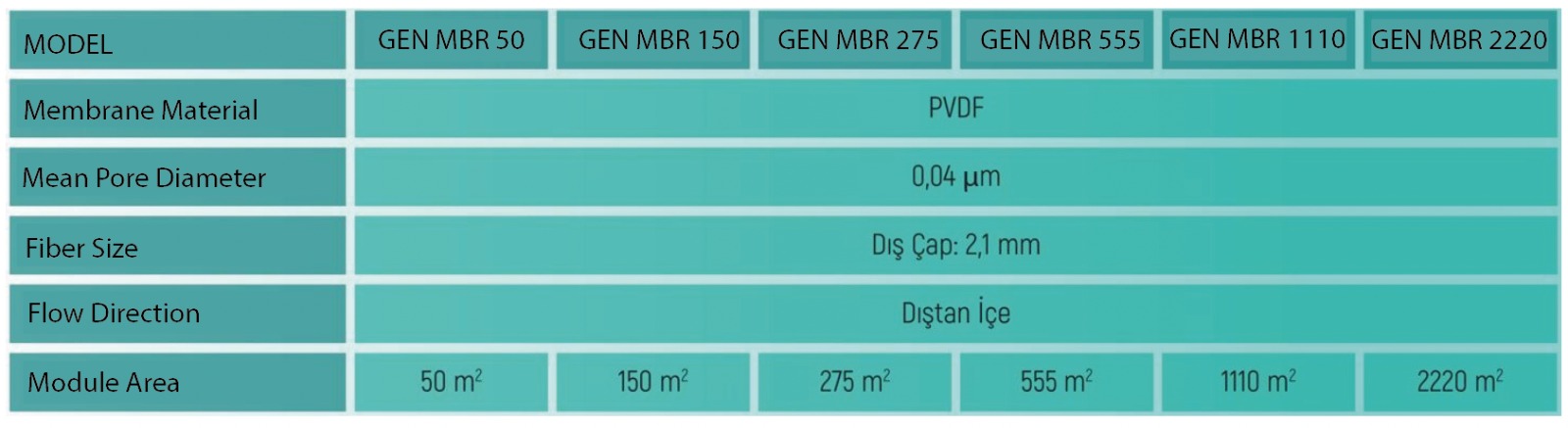

GENMBR ® Membrane Properties

The membranes we use in our modules are completely domestic production. We manufacture our membranes using PVDF polymer. It is reinforced with a special support layer (PET) and is mechanically 5 times more durable than other hollow fiber membranes. In addition, the membranes used in GENMBR ® modules have an average pore diameter of 40 nm and highly remove suspended solids, bacteria and other pathogens.

GENMBR ® Module Features

Advanced Aeration

One of the most important features of our modules is the air stripping of the contaminants on the membrane. The more effective the air stripping, the more delayed membrane fouling. Therefore, we apply aeration from different points in GENMBR ® modules. Thus, we make the air stripping effect on the membranes much more efficient.

Low Packing Rate and Modular Design

We produce modules in the form of hexagons and we can resize the modules in terms of width-length-height as needed. Therefore, this design reduces the space occupied by the module in the reactor. We place 20% more membrane area in the same reactor volume with GENMBR ® systems. In addition, we can place our modules in existing tanks according to the needs of our customers. In this way, we eliminate the additional construction cost.

As MEMSIS Environmental Technologies R&D Inc, our membrane bioreactor system, designed and installed with our GENMBR® modules, which is the first domestic product with antifouling, PET layer and reinforced hollow fiber structure, produced on an industrial scale, brings the highest quality and most cost-effective solution to our valued customers in the treatment and recovery of wastewater in your facility.

For detailed information about our products, you can contact us.